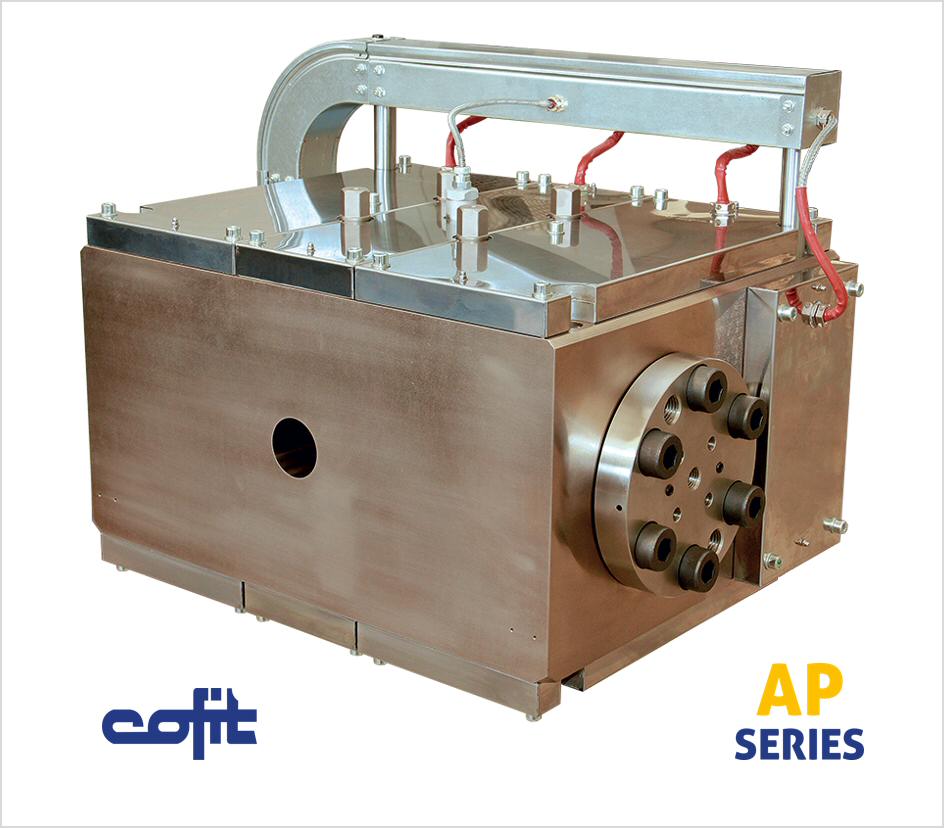

AP screen changer has two parallel filtering cartridges that are cleaned one at a time without being removed from the equipment. The flow of melt through the second filter continues while the other filter is being cleaned. With the uninterrupted extrusion process, a highly stable run is achieved. Therefore, a top-quality extrudate is produced. Also, the self-cleaning feature of AP screen changers extends the service life of screens, thus reducing maintenance activities such as filter replacement to a minimum.

Among the available continuous screen changers in the market, the AP screen changer is considered the best option since it is solid, reliable, and durable. It is also cheap and does not require expensive parts such as hydraulic units and control panels to operate. Apart from that, it is made of steel with nickel plating that serves as superior protection against wear and tear, thus ensuring its long-lasting service.

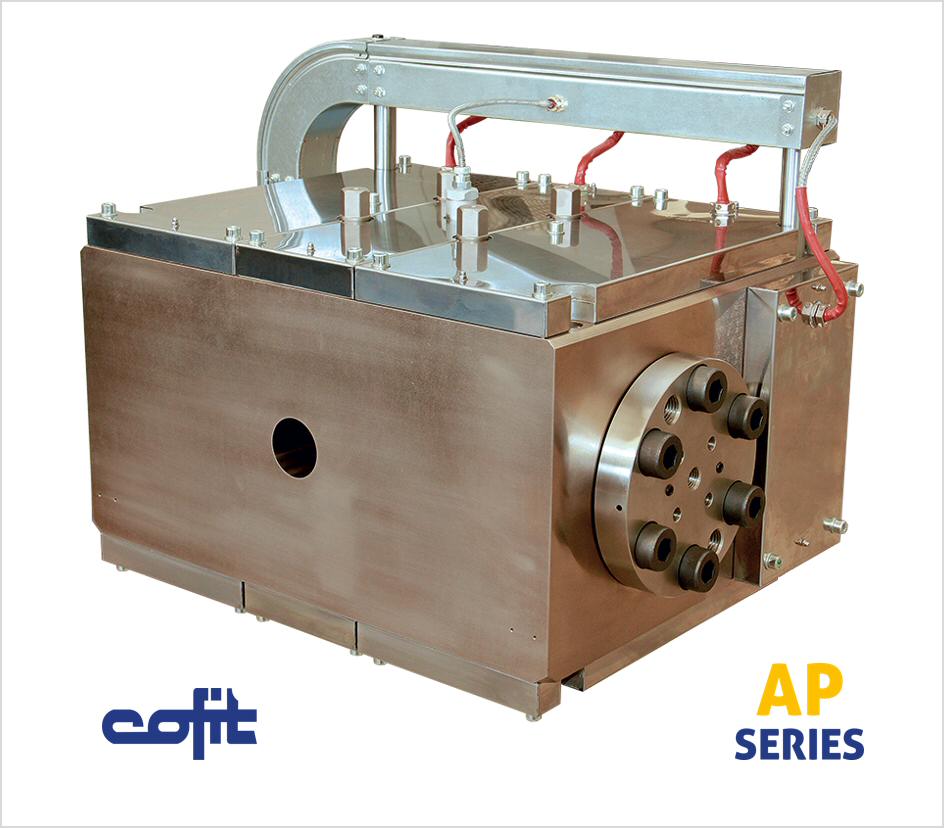

AP screen changer has two parallel filtering cartridges that are cleaned one at a time without being removed from the equipment. The flow of melt through the second filter continues while the other filter is being cleaned. With the uninterrupted extrusion process, a highly stable run is achieved. Therefore, a top-quality extrudate is produced. Also, the self-cleaning feature of AP screen changers extends the service life of screens, thus reducing maintenance activities such as filter replacement to a minimum.

Among the available continuous screen changers in the market, the AP screen changer is considered the best option since it is solid, reliable, and durable. It is also cheap and does not require expensive parts such as hydraulic units and control panels to operate. Apart from that, it is made of steel with nickel plating that serves as superior protection against wear and tear, thus ensuring its long-lasting service.

Extrusion systems must be equipped with the right filtering equipment such as a screen changer to produce high-quality products. The screen changer removes the impurities that come with the raw material and disrupts any coagulates formed during extrusion. Besides this, its usage prevents damage to downstream equipment. Furthermore, an efficient extrusion process can be achieved by using a continuous screen changer since it does not require frequent change of filter which is time-consuming and costly.

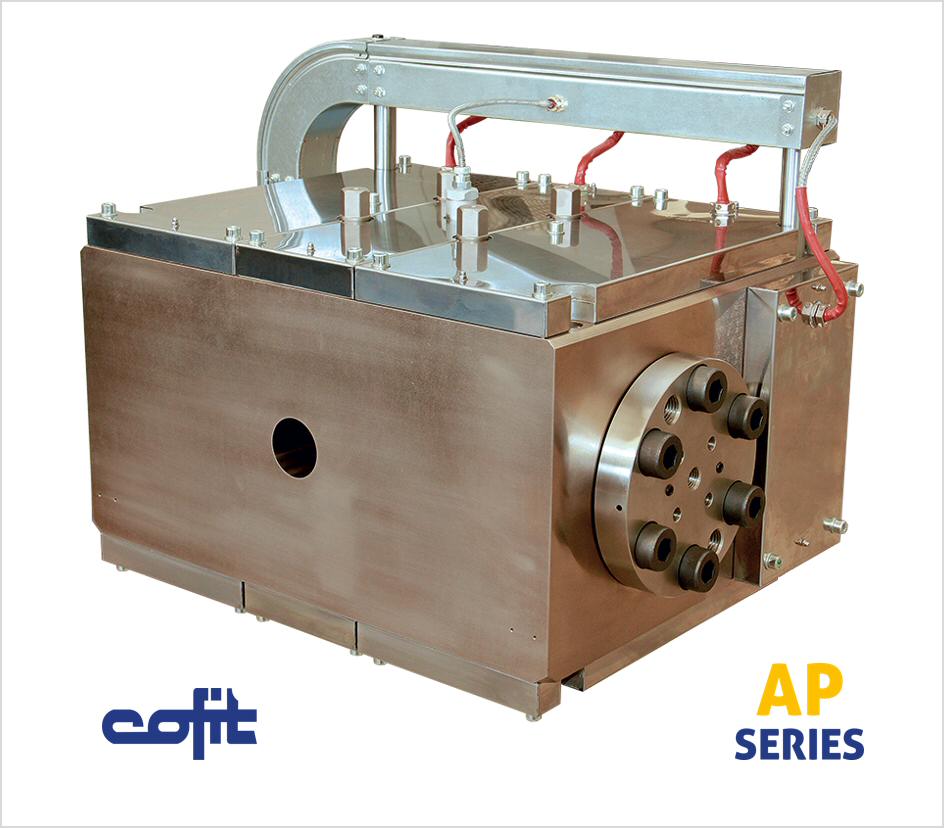

Cofit provides the best filtering solutions to extrusion systems since 1968. AP screen changer is one of the products we designed to help you improve your plastic extrusion process. It is a manual, continuous, self-cleaning screen changer suitable for low-contaminated materials such as polymers for the production of cast films and blown films, filaments and more.

AP screen changer has two parallel filtering cartridges that are cleaned one at a time without being removed from the equipment. The flow of melt through the second filter continues while the other filter is being cleaned. With the uninterrupted extrusion process, a highly stable run is achieved. Therefore, a top-quality extrudate is produced. Also, the self-cleaning feature of AP screen changers extends the service life of screens, thus reducing maintenance activities such as filter replacement to a minimum.

Among the available continuous screen changers in the market, the AP screen changer is considered the best option since it is solid, reliable, and durable. It is also cheap and does not require expensive parts such as hydraulic units and control panels to operate. Apart from that, it is made of steel with nickel plating that serves as superior protection against wear and tear, thus ensuring its long-lasting service.

AP screen changer has two parallel filtering cartridges that are cleaned one at a time without being removed from the equipment. The flow of melt through the second filter continues while the other filter is being cleaned. With the uninterrupted extrusion process, a highly stable run is achieved. Therefore, a top-quality extrudate is produced. Also, the self-cleaning feature of AP screen changers extends the service life of screens, thus reducing maintenance activities such as filter replacement to a minimum.

Among the available continuous screen changers in the market, the AP screen changer is considered the best option since it is solid, reliable, and durable. It is also cheap and does not require expensive parts such as hydraulic units and control panels to operate. Apart from that, it is made of steel with nickel plating that serves as superior protection against wear and tear, thus ensuring its long-lasting service.

AP screen changer has two parallel filtering cartridges that are cleaned one at a time without being removed from the equipment. The flow of melt through the second filter continues while the other filter is being cleaned. With the uninterrupted extrusion process, a highly stable run is achieved. Therefore, a top-quality extrudate is produced. Also, the self-cleaning feature of AP screen changers extends the service life of screens, thus reducing maintenance activities such as filter replacement to a minimum.

Among the available continuous screen changers in the market, the AP screen changer is considered the best option since it is solid, reliable, and durable. It is also cheap and does not require expensive parts such as hydraulic units and control panels to operate. Apart from that, it is made of steel with nickel plating that serves as superior protection against wear and tear, thus ensuring its long-lasting service.

AP screen changer has two parallel filtering cartridges that are cleaned one at a time without being removed from the equipment. The flow of melt through the second filter continues while the other filter is being cleaned. With the uninterrupted extrusion process, a highly stable run is achieved. Therefore, a top-quality extrudate is produced. Also, the self-cleaning feature of AP screen changers extends the service life of screens, thus reducing maintenance activities such as filter replacement to a minimum.

Among the available continuous screen changers in the market, the AP screen changer is considered the best option since it is solid, reliable, and durable. It is also cheap and does not require expensive parts such as hydraulic units and control panels to operate. Apart from that, it is made of steel with nickel plating that serves as superior protection against wear and tear, thus ensuring its long-lasting service.

Cofit deals with research, engineering, manufacture and distribution of automatic and continuous screen changers for post-consumer and post-industrial recycling materials too.

Contact us to upgrade your extrusion system, ask us for more info about any product or service.