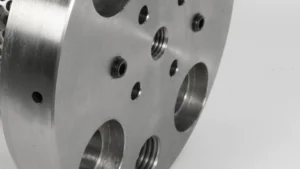

We improve the performance of the extrusion process

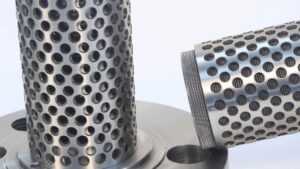

Automatic and Continuous Screen Changers since 1974

Cofit deals with research, engineering, manufacture and distribution of screen changers.

Including automatic and continuous solutions for many different plastic materials and applications, post-consumer and post-industrial recycling too.