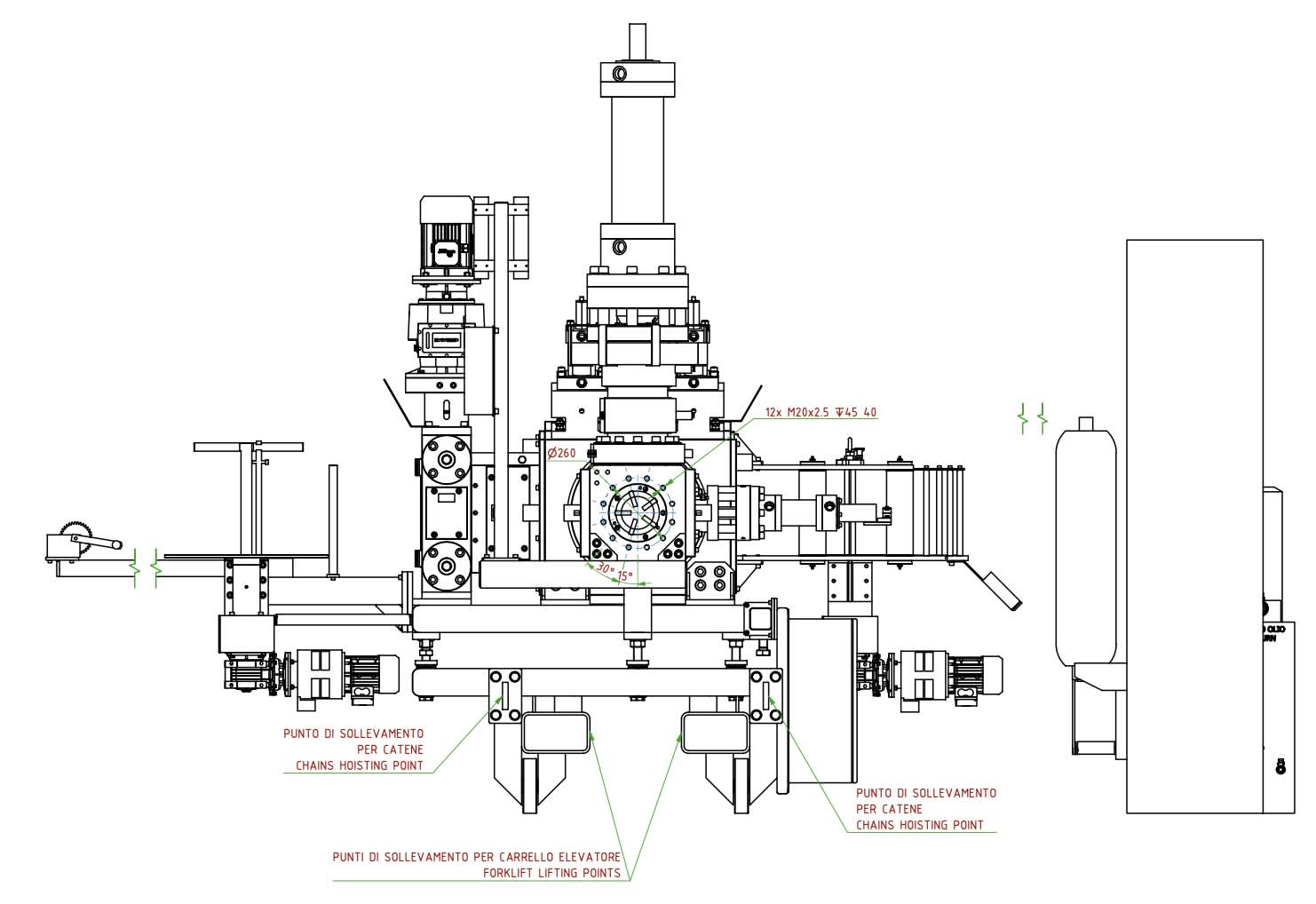

GorillaBelt Screen Changer

GorillaBelt Screen Changer

GorillaBelt is the perfect solution for post-industrial and post-consumer materials.

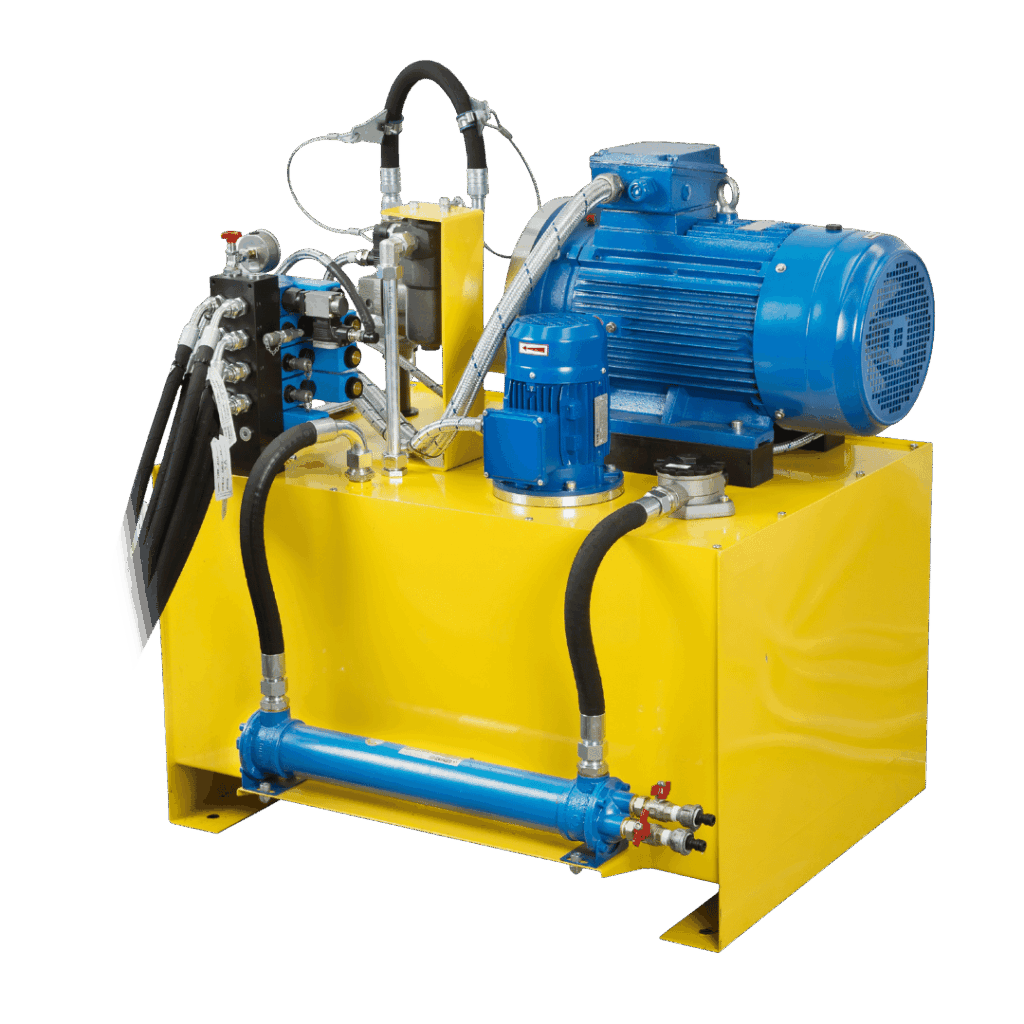

How GorillaBelt works: an automatic filter screen system prevents interruptions during the production process.

A storage cylinder allows for even very frequent screen changes while maintaining operational integrity.

Two sealing wedges minimize leaks, maximizing polymer waste.