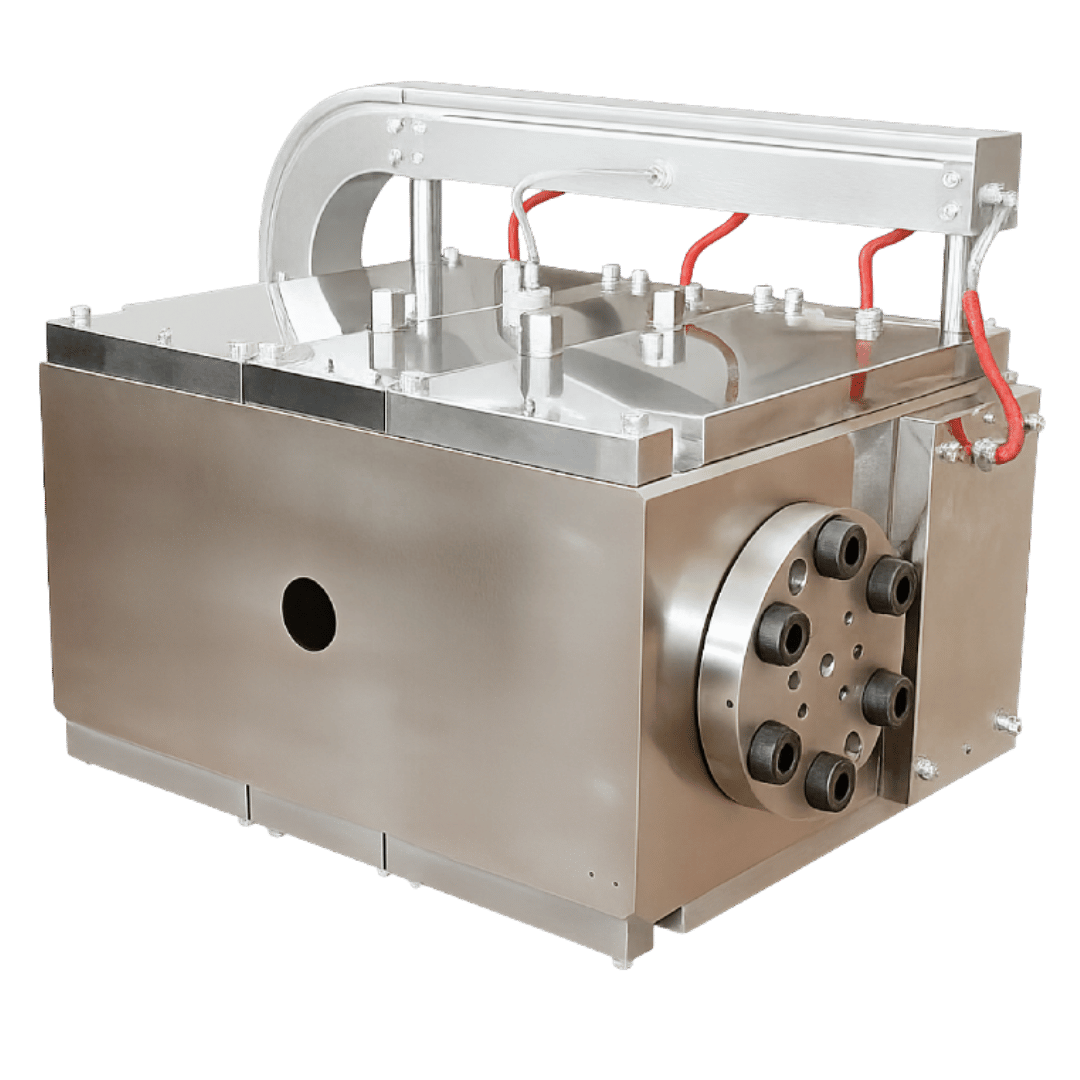

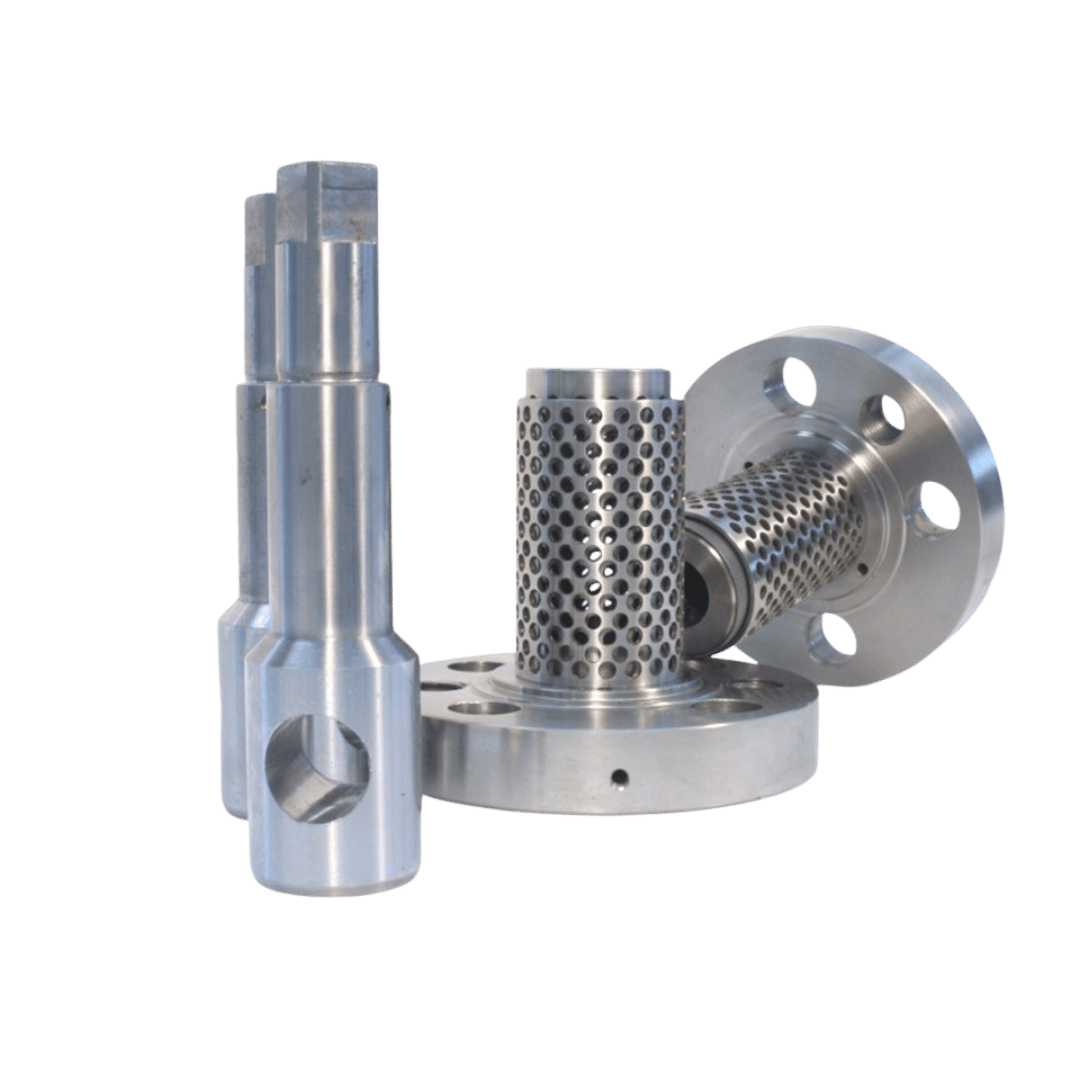

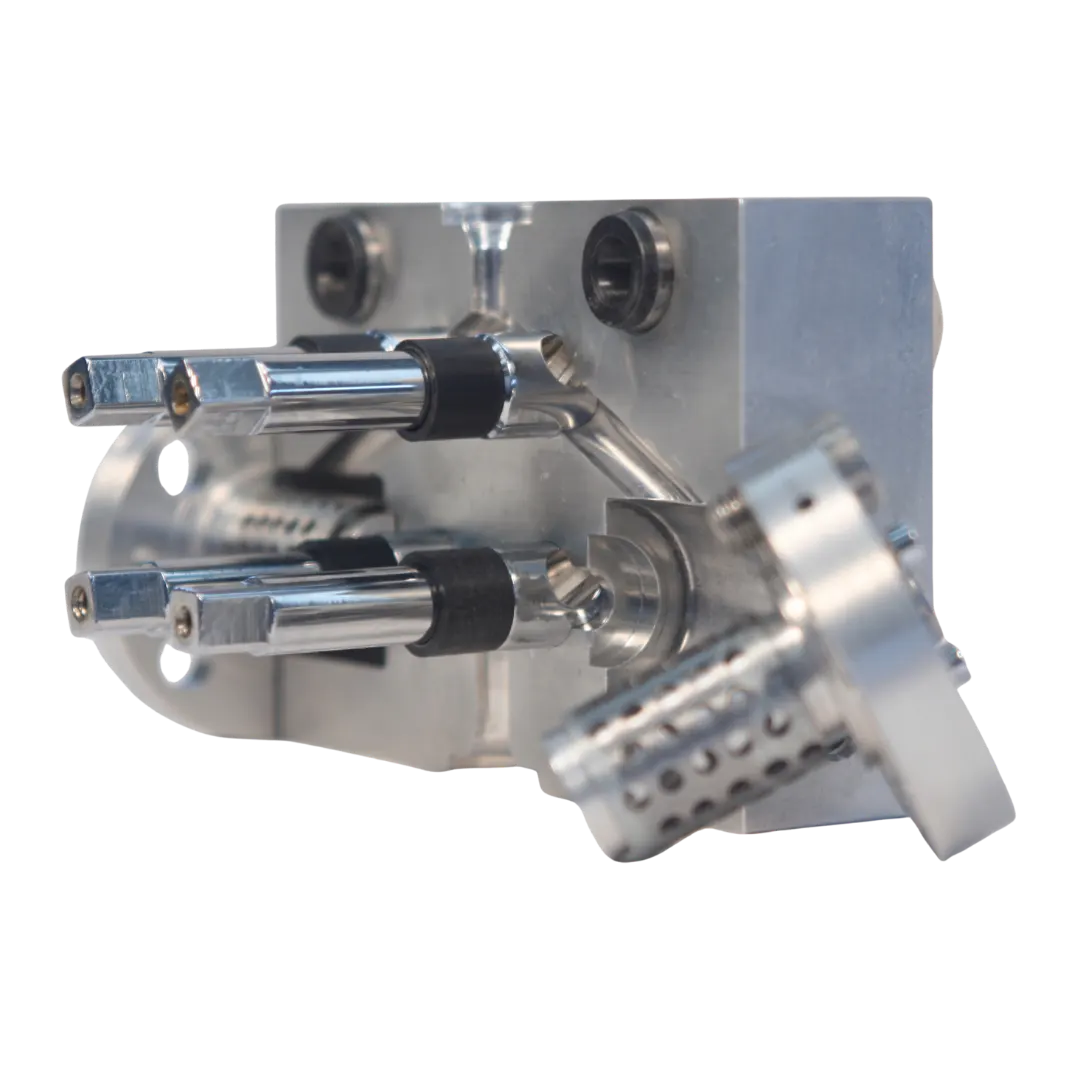

OUR SCREEN CHANGERS

AP & GorillaBelt

Since 1974, Cofit has been designing and manufacturing advanced screen changers for plastic extrusion, including fully automatic and continuous solutions. Every component is entirely made in Italy, and many of our innovations are protected by exclusive patents.

From highly contaminated post-consumer and post-industrial plastics to clean materials that do not allow any impurities, Cofit screen changers ensure uninterrupted production, exceptional filtration quality, and minimal polymer loss. They are essential to maximizing efficiency, reducing downtime, and delivering consistent, high-value output in any extrusion process.