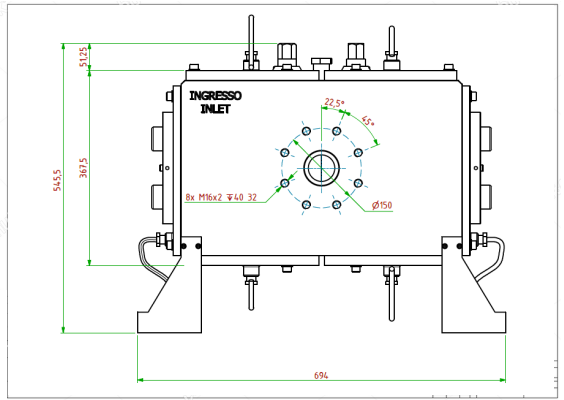

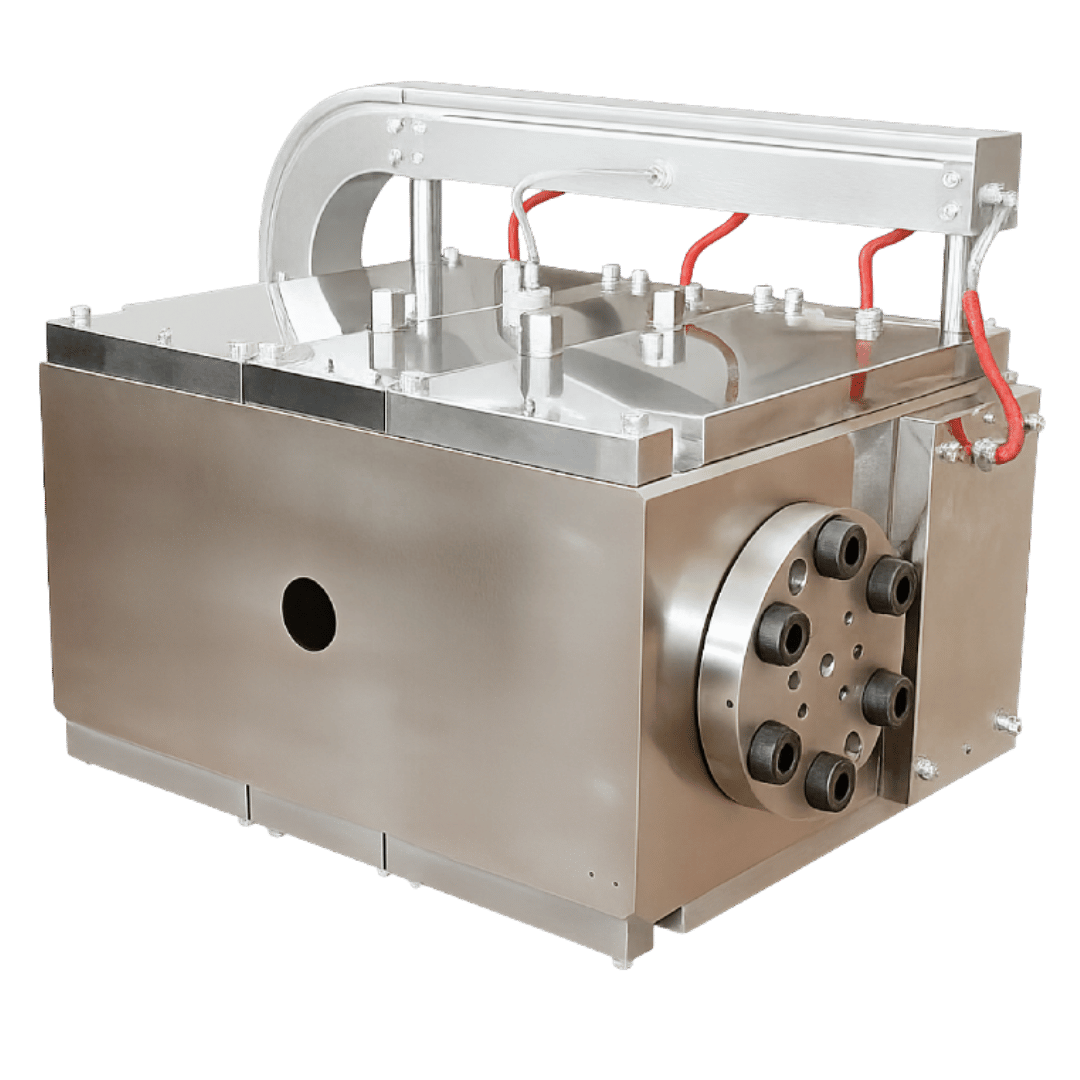

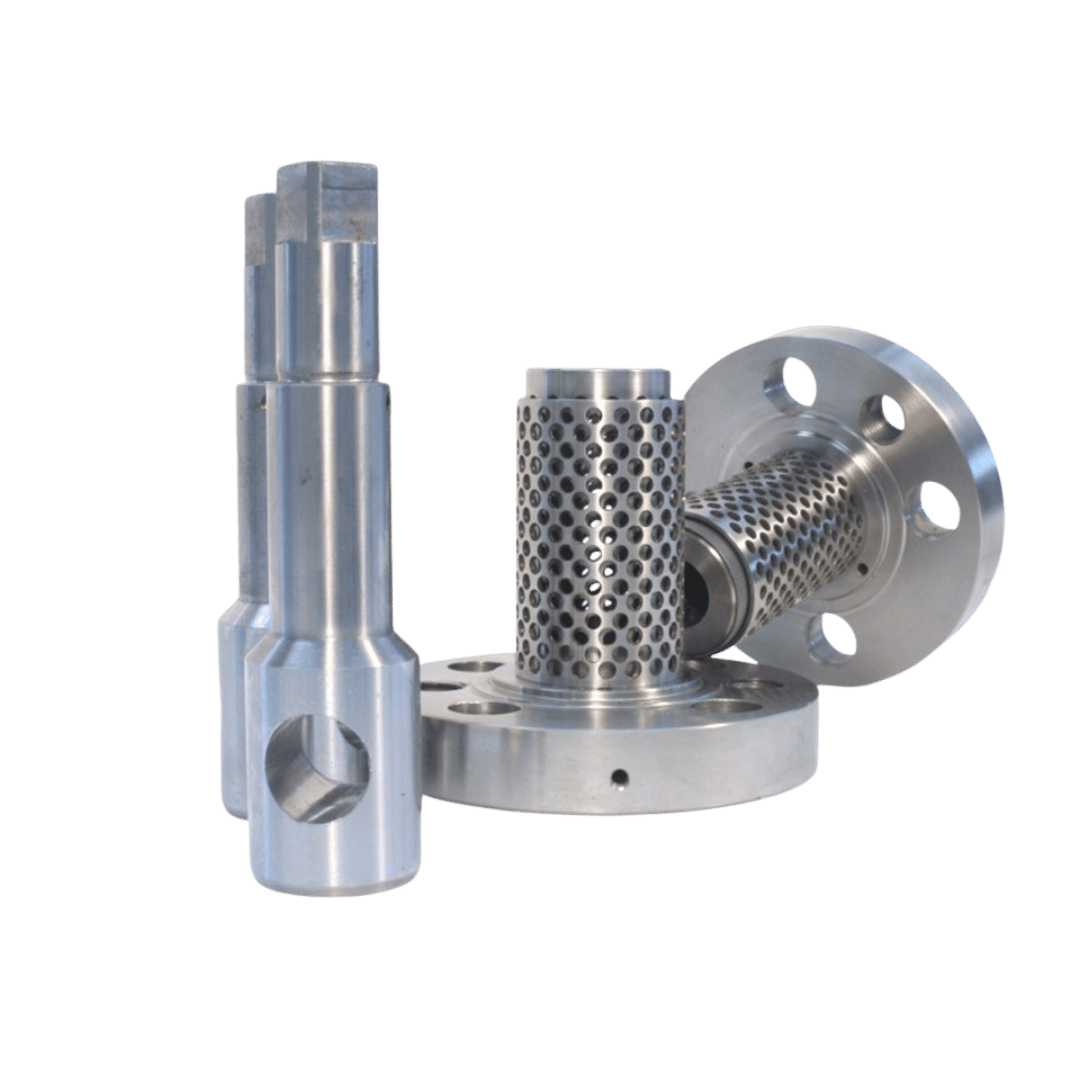

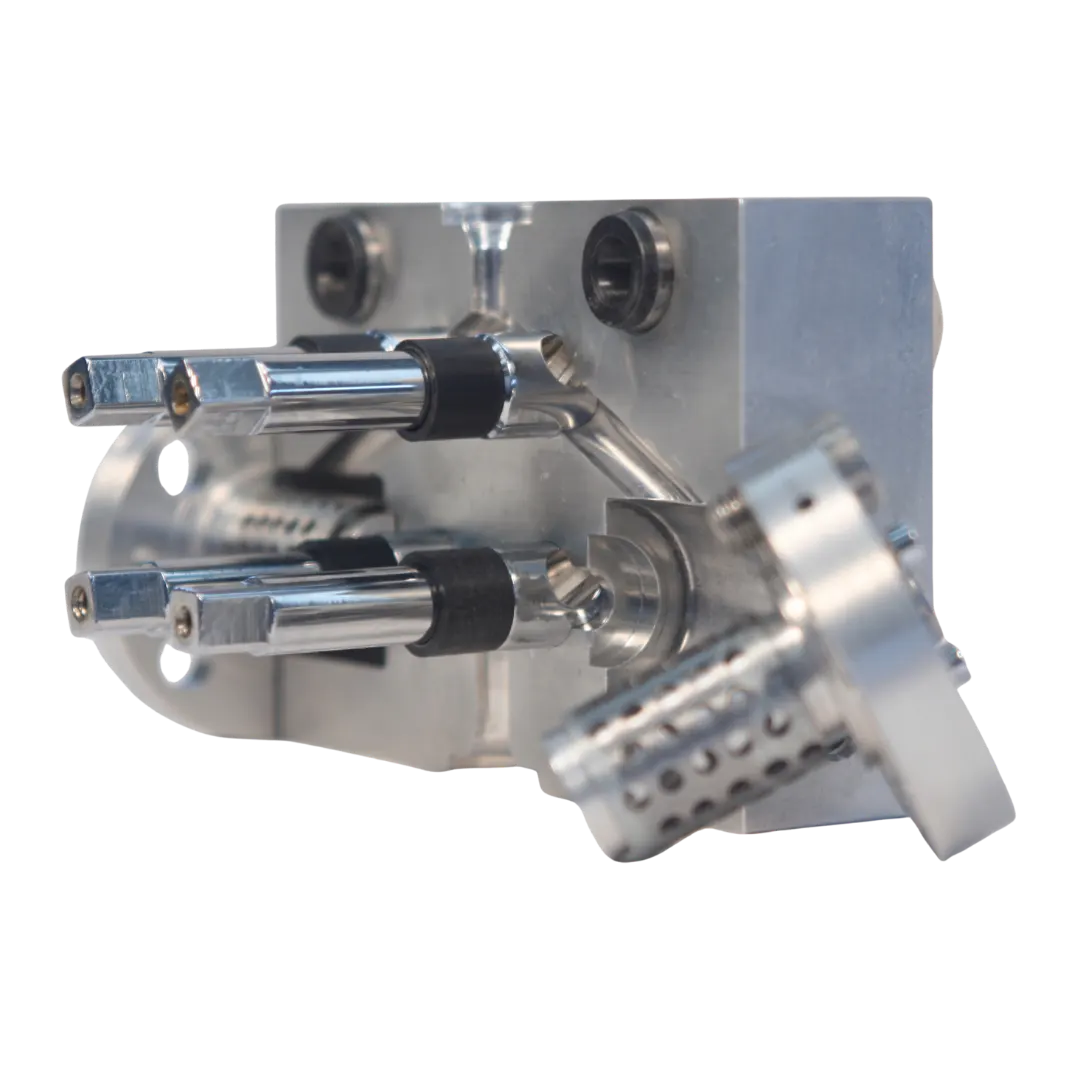

Ap screen changer

Manual continuous and self-cleaning screen changer for low-contaminated materials

AP is the perfect screen changer for low-contaminated materials. AP screen changer is entirely made in Italy by Cofit; AP is a patented product.

How AP works: AP is a continuous and self-cleaning screen changer. The AP filtering cartridges are cleaned or replaced without any interruption; your extrusion system will reach and maintain extreme stability during the extrusion run, your manufacturing process will reach top quality.